"Over the lifetime of the sensor, an accuracy of +/-0.5% of full scale (FS) is maintained. This accuracy is not affected by sensor integration, thanks to PCB-less packaging." This is how Laurent Otte, Senior Product Line Manager of Melexis highlights the main advantage of the company's recently launched new series of sensor ICs for use in automotive engine management systems.

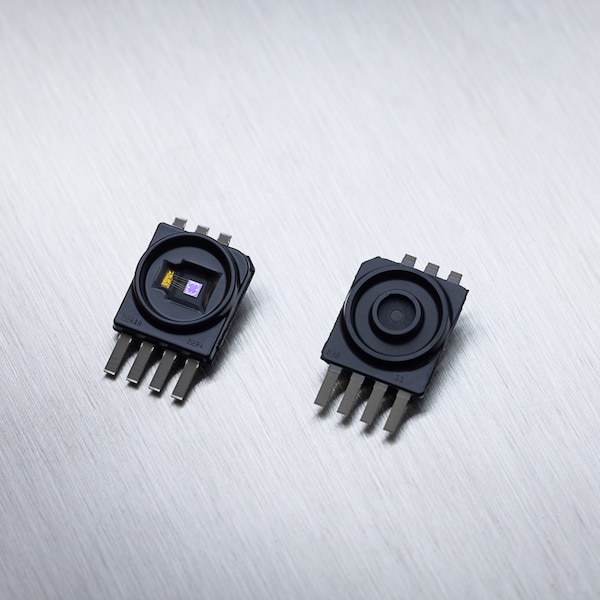

We discuss devices, calibrated at the factory, that measure pressure ranges from 1 to 4 bar: MLX90824, which determines absolute pressure, and later provides a digital output signal using the SENT protocol, and MLX90822, which provides an analog output voltage.

The MLX90824 and MLX90822 consist of a sensor readout circuit, digital hardware, voltage regulators, and SENT or analog output drivers, as well as all essential passive components. A pre-calibrated NTC thermistor input (with negative temperature coefficient) is available for the MLX90824 (with SENT output). This allows customers to interface their NTC thermistor via the pressure sensor without performing final calibration. Overvoltage (+40V) and reverse voltage (-40V) protection mechanisms are incorporated. With this range of protection, technology can be leveraged to make trucks more environmentally friendly. Pressure sensors feature an operating temperature range of -40°C to 160°C. They can also be exposed to temperatures of 170°C for a short period of time, and support supercharged powertrain architectures.

The MEMS sensing element of the MLX90824 and MLX90822 devices consists of a micromachined diaphragm connected to a cavity etched into a silicon substrate. The cavity contains a vacuum reference. The diaphragm reacts to any change in absolute ambient pressure. Piezoresistive elements implanted in the diaphragm are configured to create a Wheatstone bridge that generates a signal. The associated front-end electronics subsequently amplify the signal and convert it into a digital format. The 16-bit digital signal processor (DSP) performs temperature compensation. Finally, the result is delivered via a SENT or analog output.

"Access to stable and accurate pressure and temperature data makes it possible to manage the engine throughout the life of vehicles. This has a positive impact on fuel economy and emissions reduction," says Karel Claesen, Product Manager, Pressure Sensors at Melexis. "The MLX90824 and MLX90822 are optimized for the latest engine designs and operating conditions."

Last but not least, for motorcycles or any equipment with small motors such as chainsaws and lawnmowers among others, it is essential to have a sensor with superior update rates and step response. The MLX90822 meets this requirement with a step response 3 times faster than any other pressure sensor ever made by Melexis.

You might also be interested in:

Melexis sensors to give robots a sense of touch